EXCALIBUR® is an automatic pallet divider cutter that can be integrated into a palletizing line, replacing the traditional magazine of pre-cut formats.

THE CONCEPT

Froma reel, it produces formatsat desiredlength. The formats are then automatically transported on a conveyor to a marked position. T he gripper on the palletizer or on the robot on the palletizer retrievesthe format toinsert it between the layers of productsto be palletized . On demand, EXCALIBUR® rewinds the reel and cuts the next format. Everything your de palletizing processisautomated.

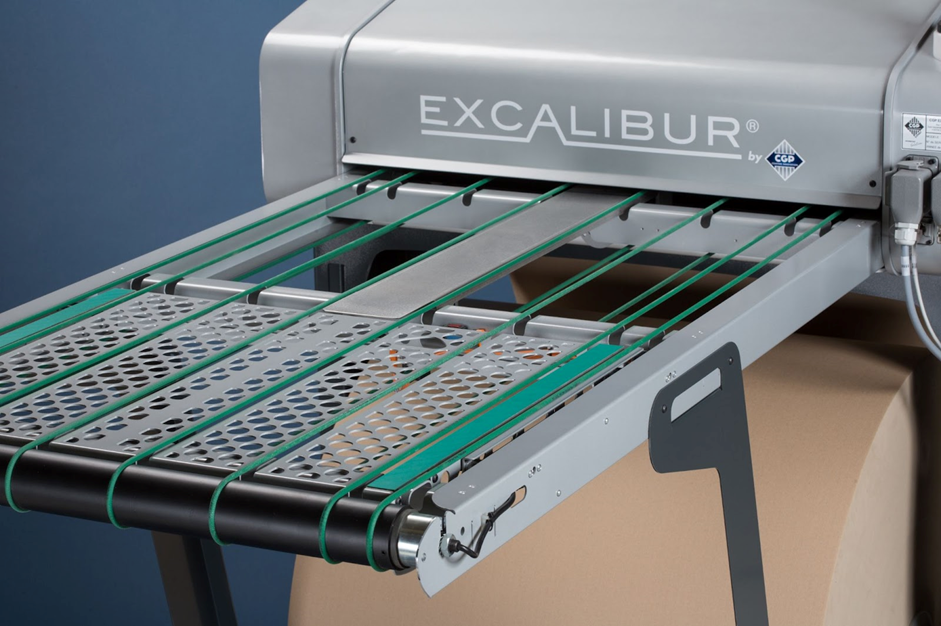

Our machine consists of :

- A head of cutting robust, reliable and low-maintenance.

- We have specially designed the cutting technology to be ideal for cutting paper;

- A table of positioning so that the different formats fit your palletizer, but also so that they can be optimized to serve the gripper arm;

- A uncoiler on axis or on cart, which enables consumables to be loaded outside the palletizer cell;

- And a HMI (Human Interface Machine) simple and accessible to all operators.

Now that you’re familiar with how it works and its components, let’s take a look at our different machine models.

5 MACHINE MODELS TO SUIT YOUR NEEDS

EXCALIBUR® BASICMODEL

This is an easy-to-use cutting machine with “Plug&Play” technology: using a forklift or pallet truck, the operator brings the reel up to the machine and loads it onto the frame by rolling it. The paper is then fed into the cutting head, and the desired cutting length is programmed on the HMI. In stand-alone mode, the machine will then cut a format each time the absence of pallet inserts is detected on the conveyor table.

EXCALIBUR® CLASSIC MODEL

The operator loads the reel onto a dedicated reel-holder cart using a forklift or pallet truck (this operation can be carried out in the raw materials warehouse). After feeding the paper into the cutter head, he can either program the desired cut length on the HMI so that the machine cuts formats in stand-alone mode, or let the line control the tool and order the reference to be produced.It can cut UNO multi-size formats, DUO half-pallets and QUATTRO quarter-pallets.

EXCALIBUR® EXTENDED MODEL

This model features an insert positioning plate that adjusts to the constraints of the gripper arm. It can be integrated on all types of automatic palletizing lines: poly-articulated robotic palletizers, high-level palletizers, low-level palletizers, bag palletizers, case palletizers, etc.

EXCALIBUR® GIRAFFE MODEL

Dedicated to high-level palletizers, this model keeps the unwinder and consumable reel on the floor, as well as the connection station and HMI controls. The cutting head and format positioning tray are positioned high up, close to the product layer composition platform. The format is delivered as close as possible to the gripper, which picks up and places the format layer on the pallet.the machine is equipped with a connecting table, thus avoiding the need for operators to move back and forth between the floor and the palletizer platform during reel changeover operations.

EXCALIBUR® BASE DISPENSER MODEL

The compact machine is positioned close to the pallet magazine, and the reel is loaded either on the wheeled carriage or directly onto the machine frame. Once cut, the format is available on the deposit tray. A Cartesian gripper arm integrated into the machine picks up the sheet and places it on the pallet. Although some models are perfectly suited to be installed in most palletizing lines, with our solutions you’ll have a high degree of flexibility for your projects.

TAILOR-MADE SOLUTIONS FOR PALLETIZING LAYER PAD MANAGEMENT

As you’ll have gathered by now, EXCALIBUR® is a modular machine. If the configuration of your line requires adaptation in order to implement our format cutters, including, in particular, modification of reel management, sheet passage or operator access to the cutter, call on our design and engineering department to design your customized solution.

Our solutions enable you to enhance the safety of your palletizing lines.

Thanks to the “IN/OUT” set-up, both the HMI and the reel are accessible to the operator, who no longer has to need to enter into the cell of palletizing, thus reducing the risk of accidents. If you can’t opt for this set-up, there’s no problem. T urn to then to a mesh safety directly attached to the base ofEXCALIBUR®. This eliminates the risks associated with handling the machine. Our engineering department is in charge of design (project studies, overall drawings, mechanical studies, detail drawings), assembly, machine installation and training of production and maintenance teams.

To benefit froma pre-study to evaluate feasibility technical your integrationproject, contact our CGP Coating Innovation experts.

GREAT FLEXIBILITY FOR FINANCING YOUR PROJECT

The various EXCALIBUR® acquisition options will enable you to benefit from a solution tailored to your needs from both an ergonomic and an economic point of view. Please note that our machine is available for purchase or as a zero investment package. This formula is subject to rental or to being made available to our customers without any contribution if a consumable supply contract is signed.

EXCALIBUR®, THE IDEAL TOOL FOR REDUCING YOUR PALLETIZING COSTS.

Our solutionsfor palletizing allow to reduce the grammage of your intercalaires : you replace your corrugated cardboard sheets with intercalaires made from paper of lower grammage.It also reduces of your numbers of references to be supplied and eliminates the need to change your consumables when changing formats. In fact, from one reel size, you can cut several sizes.

What’s more, EXCALIBUR® gives you great flexibility in managing your production, as it can operate in stand-alone or piloted mode for up to 15 references. Thanks to this system, you can do away with frequentinterventions operators to feed the store formatsand youcan thereforeallocate your workforce to productive activities.

In the management of consumables, you reduce also your stocks since you use less : 1 reel of paper replaces up to 5 pallets of corrugated cardboard !From an ergonomic point of view, loads are no longer carried manually, and consumables can be changed in complete safety thanks to the use of a wheeled cart. There y a animprovement workingconditionsof theoperators.For the “high level” palletizers, the consumable remains on the floor, but the paper reel is also loaded safely outside the palletizer cell.