Layer palletizer, Palletizing robot, COBOT, a few elements to clarify your choice.

To be transported, most products are placed on a pallet. Successful palletization is essential to ensure the continuation of the logistics process.

To automate their palletizing process, manufacturers can equip themselves with palletizers, installed at the end of the line to ensure the automatic placing of products on the pallet.

By completing the packaging line, palletizing system save significant time for palletizing goods.

Several types of palletizers exist on the market and the industry is constantly innovating. the palletizing solutions can handle products as diverse as cardboard boxes, bags, bottle packs, bundles, trays etc.

The families of automatic palletizers

Two major families of palletizer machines have emerged over the decades.

To choose the technology most appropriate to their needs, manufacturers must review their requirements (line versatility, speed, size, etc.). they must take into account the particularities of the production line, product type and the packages to be palletized.

What are the two main families of palletiser automation?

1. The so-called conventional layer palletizers

In the case of layer palletizers, the preparation of the product layer precedes palletizing.

The packages, assembled in entire layers, are placed on a tray. when the tray opens, it allows them to be placed, layer by layer, on the empty pallet.

There are two types of conventional palletizers:

- High-level layer palletizers (high entry)

High-level palletizers are constructed so that the wooden pallet receives the layers of packages upstairs, then descends as layers are added. - Low-level layer palletizers (low entry)

Low-level palletizers are constructed so that the wooden pallet remains on the lower level, and the layers of packages are mounted higher and higher.

When the palletization plan requires the insertion of non-slip interlayer formats between the layers of packages to ensure their stability, a dedicated gripper must be installed in the line.

This gripper is often equipped with vacuum pumps, suction cups and other pneumatic components.

Its sole function will be to take pre-cut insert formats which are positioned in whole stacks in a magazine. Instead of this magazine, an EXCALIBUR® insert cutter can also be installed, supplied with reels of STABULON® anti-slip paper. This cutter will cut the formats one by one, according to the needs of the palletiser and present a single intermediate format on its conveyor table.

2. Palletizing robots

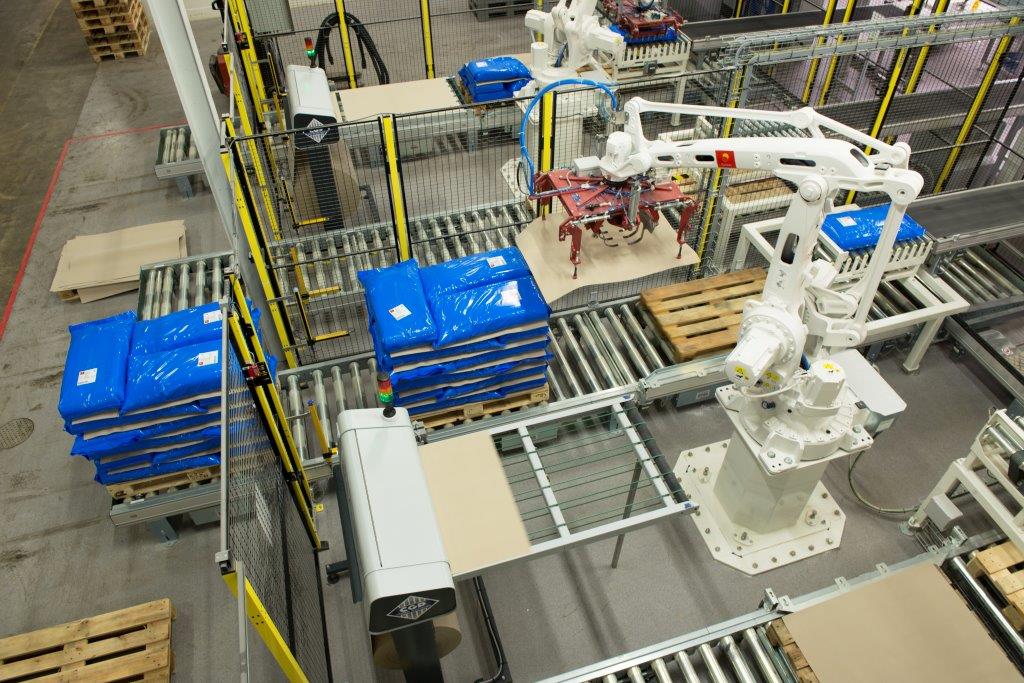

In the case of palletizing robots, most of the line is located on the floor level. The palletising robot is enclosed in a safety enclosure to protect the operators.

The palletizing robot is equipped with one or more gripping heads to perform different tasks at the same time:

- Take the packages and position them on the pallet following a defined palletization plan.

- Possibly take the wooden or plastic pallets from the pallet dispenser in order to position them where the layers of packages will be formed.

Between each floor, the robot can be brought to position a paper interlayer like STABULON® to ensure the stability of the pallet.

The robot then comes to use in a stack of dividers positioned in a store within the robotic cell.

To feed this magazine, an operator must enter the cell and load the magazine. Instead of this magazine, an EXCALIBUR® insert cutter can also be installed, supplied with reels of STABULON® anti-slip paper. This cutter will cut the formats one by one, according to the needs of the palletizing robot. It will present only one insert format at a time on its conveyor table.

To learn more, about how a key European player in the manufacture of breakfast cereals succeeded in automating their entire palletizing chain.

Conventional palletizer VS. Robot palletizer, How to make the right choice?

Robots are flexible, layer palletizers are fast. Each of the two families of palletizers have their advantages. Palletizing robots are often cheaper solutions than layer palletizers.

They are, for an industrialist, a good entry ticket into the world of automation. Fairly flexible, they can be fed by several packaging lines at the same time. It can handle different types of pallet patterns and palletize several sizes of pallets at the same time.

However, because by nature they have several roles to play (picking up packages, picking up interleaves, depositing pallets, etc.), the cycle times of palletising robots are limited. Furthermore, the more the number, shape and nature of the objects to be handled vary, the more complex and heavy the gripper will be. Its cost can represent a significant part of the overall cost of the robotic cell.

Because they handle entire layers of packages at once, the biggest advantage of layer palletizers is their throughput. Some models of palletizers can palletize up to 10 layers per minute. Very reliable by reputation, they offer optimum respect for the products.

More and more blurred borders

Today, the boundaries between families of palletizers are porous. Mixtures have always made beautiful children. In recent years, palletizer manufacturers and integrators have started to combine technologies to get the best out of each of the two families.

For example, we see more and more palletizing lines equipped with robots, with very sophisticated grippers, to take entire layers of packages prepared upstream.

Palletizing COBOT

As for Cobots (collaborative robots), equipped with an arm tool “user friendly”, they make it possible to share workspace and facilitate human-robot collaboration.

They are also making their entry into the family of palletizers.

There is no doubt that in the next few years many innovations will change the palletizing world as we know it today.