Which is the best option ?

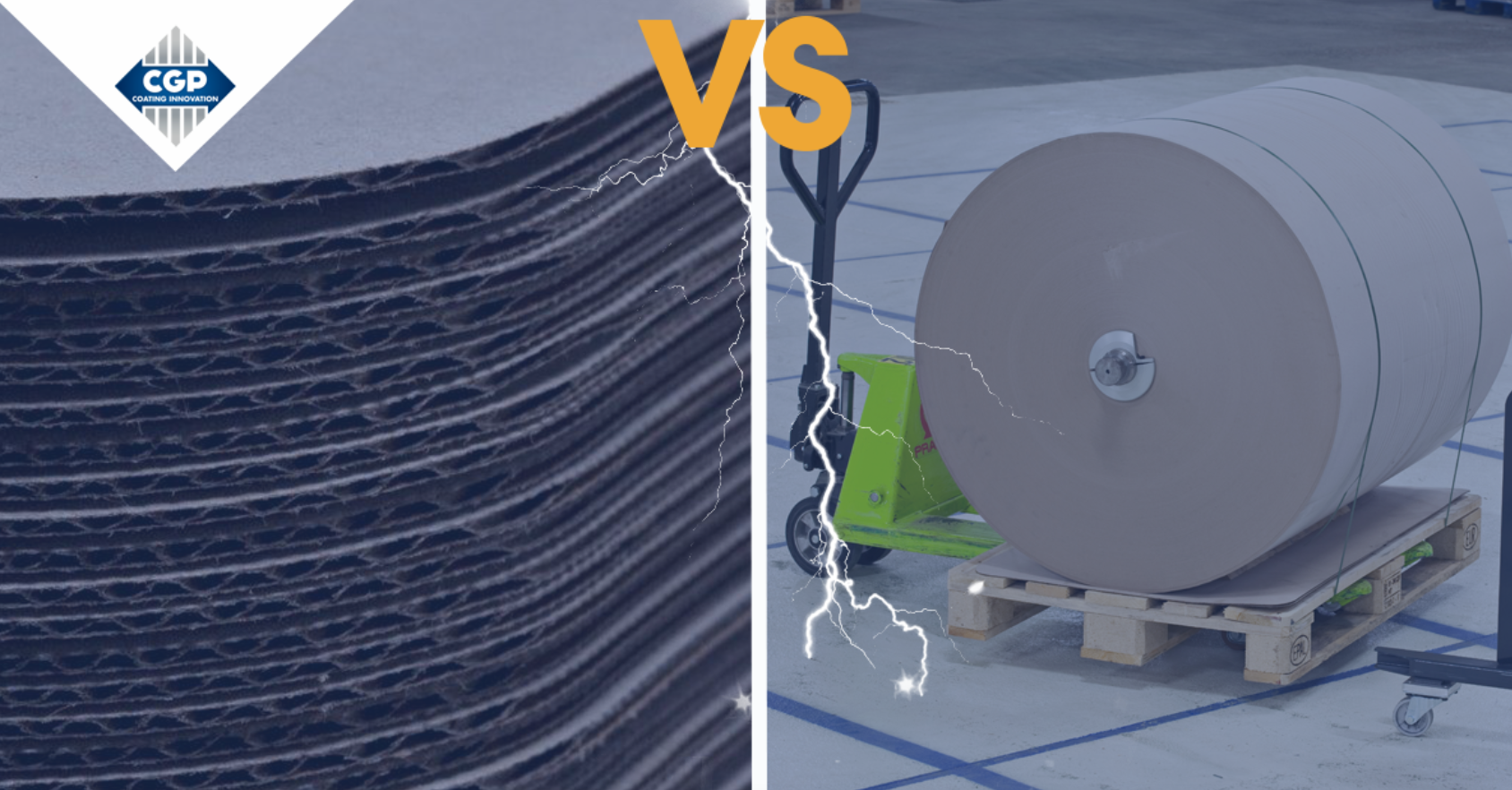

Did you know that by opting to replace and cut anti-slip paper inserts on your production lines, you multiply your chances of reducing both direct and indirect costs?Let’s take a closer look at how the introduction of one format at a time at the palletizing line’s gripper has a positive impact on reducing your costs.

The use of anti-slip paper inserts on reels to be automatically cut on EXCALIBUR® machines allows you to:

1. Receive fewer raw materials

Corrugated cardboard sheets are delivered to fit the dimensions of your pallets. Each pallet of corrugated cardboard sheets you receive contains between 300 and 500 units, depending on sheet thickness. The relatively limited number of corrugated sheets per pallet means that replenishment is frequently required.

The introduction of the EXCALIBUR® insert cutter solves this problem. Thanks to this machine, you can place fewer orders, since it produces customized formats from a single reel. In addition, it ensures smooth operation of the insert gripper.

2. Save storage space

Unlike corrugated cardboard, the use of anti-slip paper inserts on reels, cut automatically with the EXCALIBUR® machine, has the advantage of requiring less frequent replenishment.

This approach avoids taking up too much storage space: a single reel of paper contains as many inserts as 10 pallets of corrugated sheets. Feeding is carried out using a single reel reference, enabling the production of up to 15 lengths of various formats. Therefore, with anti-slip paper reels, you can reduce both your transport costs and your storage space requirements.

3. Fewer line stops to reload the magazine

The consumption of an 800 to 1000-mm diameter reel lasts longer than the consumption of a pallet of corrugated cardboard formats, thus reducing production interruptions for sheet replenishment. Unlike traditional methods, there are fewer stops to refill the sheet reservoir.

In the latter case, the operator has to stop the production line when replacing the pre-cut corrugated board pallet. This requires the operator to enter the palletizer cell, bringing the packaging line to a complete halt. This safety procedure has an impact on productivity. Our palletizing system minimizes or even eliminates reel changeover times.

Our machine offers the possibility of loading the reel outside the safety cell, thus standardizing part numbers, reducing production time, and increasing flexibility and productivity.

4. Always have the format in the same position: robots spend less time picking up sheets

EXCALIBUR® cuts formats of any length from a single reel. These formats are then automatically conveyed via a conveyor system to a designated position. The palletizer or palletizing robot gripper then picks up the format and inserts it between the rows of products to be palletized. On request, the machine can rewind the reel and cut the next format.

5. No more gripping errors

When using traditional pallet inserts on an automatic palletizer, accidental sheet falls into the palletizing cell often occur, potentially blocking sensors and stopping the entire production line for safety reasons.

Our EXCALIBUR® machine solves this problem by feeding the robot a single sheet at a time, eliminating the accidental dropping of insert sheets. What’s more, it improves grip quality, eliminates gripping problems, and ensures greater pallet stability thanks to its unique non-slip coating. This makes your palletizing process even more efficient.

6. Reduce paper weight

By using anti-slip paper formats on reels, you can considerably reduce the number of orders you place with your suppliers, thanks to the lower paper weight. This savings can represent between 25% and 50% of what you spend on consumables.

With our anti-slip paper combined with the EXCALIBUR® machine, you gain flexibility:

- By adjusting the quality of the paper insert thanks to grammage reduction and adding anti-slip properties to guarantee optimum pallet stability.

- By producing precisely the length required.