Did you know that container rain can cause damage to your cargo?

Discover our solutions to face condensation in containers.

As you may already know, all containers contain moisture at the time of loading, none are spared. Moisture moves in and out of the container during the journey, which can cause damage to your goods. In addition, there are some uncontrollable phenomena, such as the weather, which can affect your cargo during shipping.

But this damage can be avoided if you take the necessary precautions to protect your products from “ container rain.”

And you know what? We have several solutions to offer you.

Before that, let’s take a look at what “container rain” is and the different factors that can cause damage to your goods during international shipping.

What the term “container rain” means:

Container rain is moisture that condenses and forms on the interior surfaces of the container.

The water accumulates, concentrates into larger and larger drops, and then falls due to their weight. Thus, container rain is born, which then falls directly on the cargo.

So as you now see, container rain is complex to avoid, that’s why.

here are 3 main factors that can cause damage to your goods during international shipping:

1. Loading and weather conditions

If you are loading your goods near a river or sea port, then there is already high humidity in your container.

In addition, when a container is filled during rainy weather or even in the rain, the water deposited on the goods evaporates. This happens once the container warms up, but condenses again as it cools during the journey. This is due to the difference in temperature between day and night.

You have no control… You will not change your address and you will not decide the weather of the day.

2. Packaging materials, natural moisture content, and moisture absorption rates

Some packaging materials such as wood, paper, and cardboard have hygroscopic properties, i.e., they absorb or release moisture from the ambient air. This contributes to the moisture content inside your container, which increases the risk of condensation problems. Here again you have little room to maneuver, you can’t always go without cardboard packaging or wooden pallets!

3. Moisture in your product! and lack of ventilation

Did you know that food products, such as coffee, cereals, and flour, give off a lot of ambient humidity? Depending on the nature of the product, its moisture content, and its ability to release it will differ.

And as you can imagine, a container is, in essence, an almost enclosed space. As a result, the lack of ventilation prevents air circulation, which also leads to this accumulation of moisture.

Now that we have seen the different damage factors, here are three solutions to prevent moisture damage.

1. Ventilation, mechanical dehumidifiers, or anti-condensation sprays

Release the excess moisture in your container! Do not hesitate to make use of a ventilation system to increase the airflow inside your container. The more air circulates in a container, the less contrast there is between the inside and outside temperatures, thus reducing the risk of condensation.

Dehumidifiers inside the container to remove moisture from the air also work. Some of these units include an automatic on/off switch that reacts to the amount of humidity in the air and saves energy. There are also anti-condensation coatings to be applied to the ceiling and the six interior sides of the container. This also limits the effects of condensation.

2. Moisture absorber in bags or boxes or thermal container liner.

Are you familiar with the bags or boxes that absorb moisture? These are non-mechanical devices that fit into the corrugated sidewall of the container. The salts inside absorb moisture from the air and release it into a gel that forms a reservoir. However, care must be taken to ensure that these accessories are not placed above or in contact with the products.

You also have the option of using thermal container liners that can help regulate the temperature inside the container.

As you understand, preventing condensation is almost impossible for standard shipment. The best you can do is to reduce condensation by reducing the amount of moisture, but it is not simple to organize.

If you want to prevent physical damage with a cost effective solution within your international shipments, you should consider the following packaging tools.

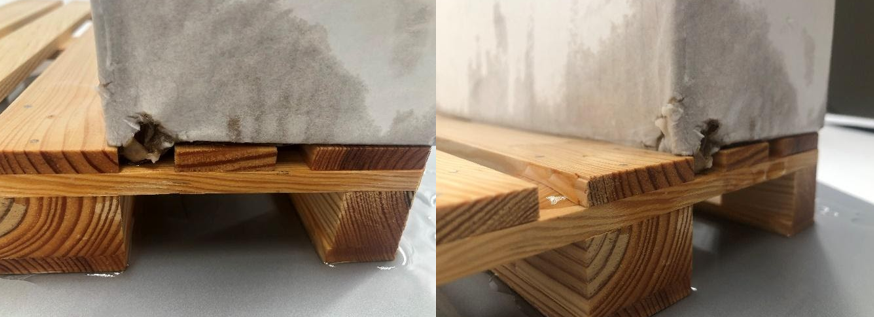

3. Hydrophobic palletizing inserts

Finally, we’ve saved the best for last! Hydrophobic palletizing inserts.

They block the water that rises by capillary action from the wooden pallet.

Did you know that a wooden pallet can absorb up to 15 liters of water?

In order not to damage your brand image, you should use non-slip and water resistant

WITH DIVIDER WITHOUT THE DIVIDER

We have a wide range of hydrophobic inserts to avoid contamination damage:

Hydrophobic paper-based inserts:

AQUASTOP® and STABULON® OCEAN.

Plastic inserts: STABUFILM® and its STABUFOOD® version dedicated to use in the food industry.

Using these products assures stable pallets, which will avoid damage related to the increasing dampness of wooden pallets.

Placed at the foot of the pallet, they protect the products against the roughness and dirt of wooden pallets.Resistant and forming a water barrier, they protect the products against moisture or inter-layer accidents.

Anti-slip, they both avoid accidents linked to palletized loads sliding off the pallet.

Ideal for securing and stabilizing products in damp or wet environments.

We are here to help: contact our experts!