We all face major environmental challenges in our daily lives.

This includes the packaging we manufacture and use.

As a manufacturer of packaging solutions, CGP COATING INNOVATION has long been looking for ways to reduce its impact and that of its customers, with alternatives that are less harmful to the environment, but just as effective in protecting and stabilizing goods. To achieve this, CGP Coating Innovation teams are constantly working to improve all the products we manufacture:

- by sourcing sustainable materials from suppliers,

- by designing solutions to be environmentally friendly,

- by reducing CO2 emissions at every stage of the manufacturing process.

There are many ways to reduce your environmental impact, and we are here to help.

How do you recognize environmentally responsible packaging?

There is no official definition of “environmentally responsible” or “sustainable packaging”. It was designed to contribute to sustainability and environmental protection. It offers opportunities for recycling, reuse, and composting.

Recycling packaging is an effective way of reducing your environmental impact, as it enables the reuse of existing materials and thus reduces waste pollution.

To determine whether your packaging is sustainable, you need to ask yourself the right questions:

1. Is the material used to manufacture the packaging renewable or recycled?

A renewable material is one made from natural resources that regenerates naturally and quickly, helping to shrink your environmental footprint.

2. Is the packaging reusable or recyclable?

Recyclable packaging is packaging that can be processed for re-use. This process reduces waste and pollution, and helps preserve natural resources by using existing materials rather than creating new ones.

3. Do the packaging and machinery used throughout the logistics process have a low carbon footprint?

The packaging and machinery you choose for your logistics process will help to reduce your carbon footprint by choosing the right materials and reducing the use of plastic film.

How can CGP Coating Innovation help you?

Going green is part of a regulatory and fiscal framework. The trend is unstoppable, and markets are closing in on the least environmentally-friendly companies. That’s why CGP Coating Innovation helps you design a product that meets environmental requirements right from the start. This is what we call eco-design..

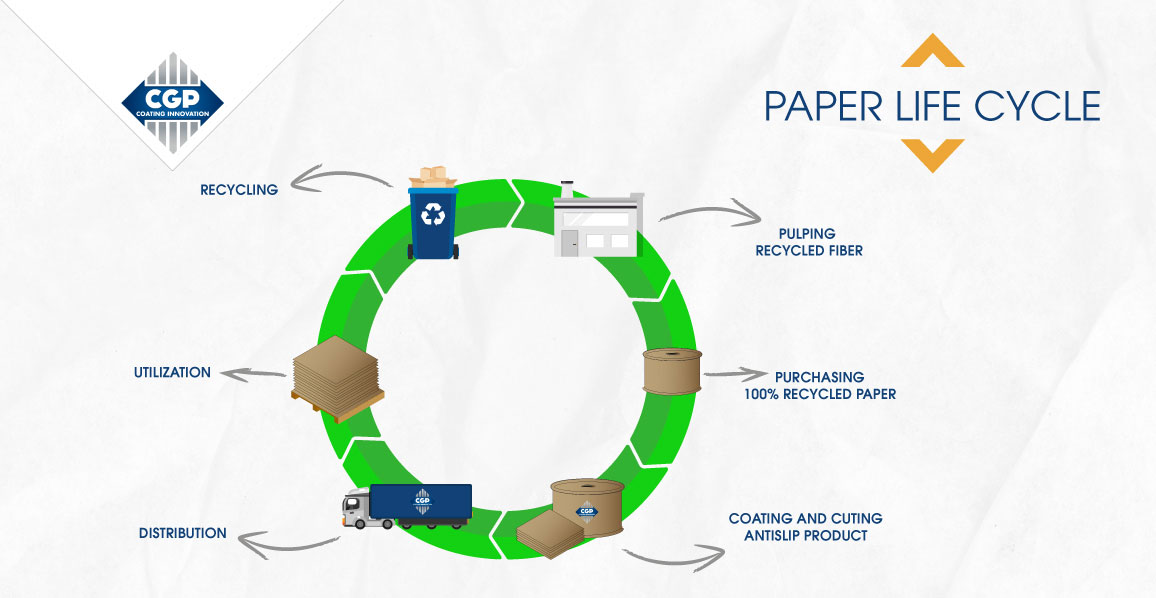

Eco-design involves integrating environmental protection into the product design process. The goal is to minimize the environmental impact at every stage of the life cycle, including raw material extraction, manufacturing, distribution, use, and end-of-life.

The process often begins with an analysis of a product’s life cycle. This analysis assesses the product’s overall impact. It is based on 14 observation indicators divided into six major families. It thus offers avenues for improvement on the most significant criteria.

Today, the Group is constantly developing environmentally friendly solutions to meet its customers’ needs. Along with its teams, the Group has developed a complete range of STABULON® anti-slip pallet inserts, with an environmentally friendly design while retaining the same characteristics to ensure the safety of your products.

Our STABULON® range is 100% recyclable.

It allows you to reduce and optimize your packaging and logistics costs, in particular by reducing the use of stretch film. But it also helps to reduce damage during transport or internal conveying, and reduces workplace accidents on packaging lines, in storage warehouses, and during loading and unloading operations.

With STABULON®, you can eliminate secondary or tertiary packaging for simplified de-palletization, and optimize your storage and transport areas.