Layer palletizer, palletizing robot, COBOT, a few points to help you make your choice.

To be transported, most products are placed on a pallet. Successful palletization is essential to guarantee the rest of the logistics process.

To automate the palletization process, manufacturers can install palletizers at the end of the line to automatically place products on pallets. By complementing the packaging line, palletizers save considerable time when palletizing goods.

There are several types of palletizer on the market, and the industry is constantly innovating to handle products as diverse as cardboard boxes, bags, packs of bottles, packets, trays, and so on.

AUTOMATIC PALLETIZER FAMILIES

Two main palletizer families have emerged over the decades.

To choose the technology best suited to their needs, manufacturers must review their requirements (line versatility, speed, footprint, etc.) and take into account the specific features of the packages to be palletized.

What are the two main families of palletizers?

1 – CONVENTIONAL LAYER PALLETIZERS

In the case of layer palletizers, the preparation of the product layer precedes palletizing: the packages, assembled in whole layers, are placed on a tray whose opening allows them to be placed, layer by layer, on the pallet.

There are two types of conventional palletizer:

- High-level layer palletizers (high infeed)

These palletizers are designed so that the wooden pallet receives the layers of parcels on the upper level, then descends as the layers are added.

- Low-level layer palletizers (low entry)

These palletizers are designed so that the wooden pallet remains on the lower level, while the layers of packages are added higher and higher.

When the palletizing plan calls for the insertion of non-slip interleaf formats between the layers of packages to ensure their stability, a dedicated gripper must be installed in the line, often equipped with vacuum pumps, suction cups and other pneumatic components. Its sole function is to pick up pre-cut insert formats, which are placed in whole stacks. To find out more, read how a key European player in the manufacture of breakfast cereals succeeded in automating its entire palletizing chain in one warehouse.

In place of this warehouse, an EXCALIBUR® interleaf cutter fed with rolls of STABULON® anti-slip paper can also be installed. This cutter will cut the formats one by one, as and when required by the palletizer, and present a single interleaf format on its conveyor table.

Find out more about how a key European player in the manufacture of breakfast cereals succeeded in automating its entire palletizing chain;

2 – PALLETIZING ROBOTS

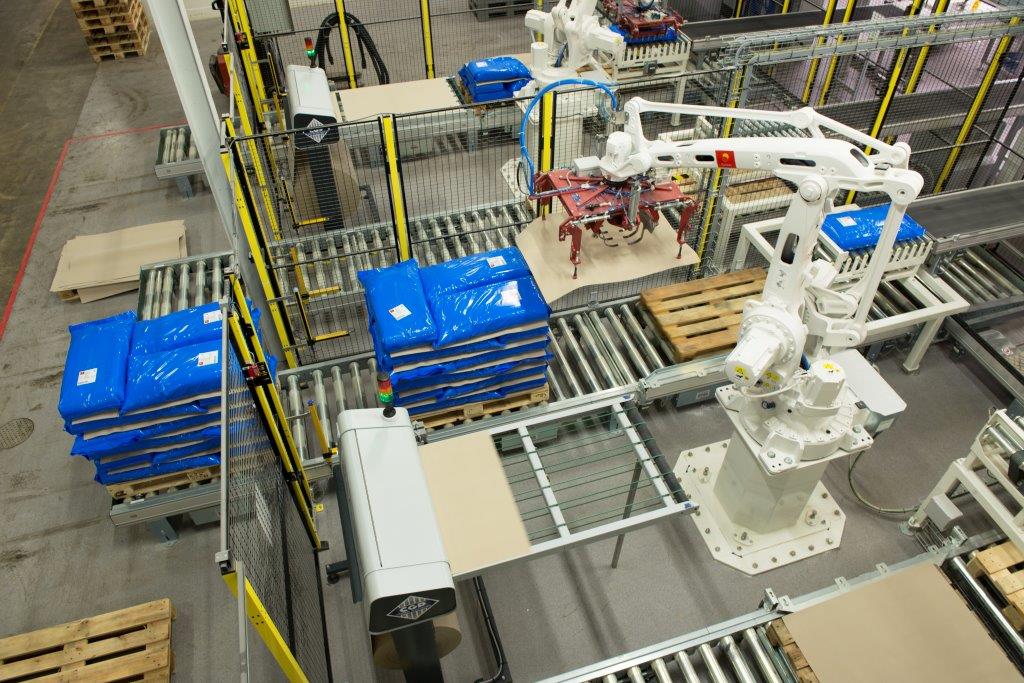

In the case of palletizing robots, most of the line is located on the first floor. The palletizing robot is enclosed in a safety enclosure to protect operators.

The palletizing robot is equipped with one or more gripper heads to perform different palletizing tasks at the same time:

- Pick up packages and place them on the pallet according to a defined palletization plan.

- It may also pick up wooden or plastic pallets from pallet racks and place them where the layers of packages are to be built up.

Between each layer, the robot may need to place a paper insert such asSTABULON® to ensure pallet stability .

The robot then draws from a stack of dividers placed in a magazine within the robot cell. To feed this magazine, an operator must enter the cell and load the magazine. Instead of this magazine, an EXCALIBUR® div ider can also be installed, fed with reels of STABULON® anti-slip paper. This cutter will cut the formats one by one, as and when required by the palletizing robot. It will present only one format at a time on its conveyor table.

PALLETIZER vs. ROBOT PALLETIZER, HOW TO MAKE THE RIGHT CHOICE?

Robots are flexible, layer palletizers are fast. Both families of palletizers have their advantages.

Robotic palletizers are often a less expensive solution than layer palletizers. For manufacturers, they are a good entry ticket into the world of automation. Quite flexible, they can be fed by several packaging lines at once, and palletize several pallet sizes at the same time.

However, since by nature they have several roles to play (picking packages, picking layer pads, depositing pallets, etc.), palletizing robots have limited cycle times. Moreover, the more the number, shape and nature of the objects to be handled vary, the more complex and heavy the gripper will be. Its cost can represent a significant proportion of the overall cost of the robotic cell.

Because they handle whole layers of packages at a time, the greatest advantage of layer palletizers is their speed. Some palletizer models can palletize up to 10 layers per minute. Highly reliable by reputation, they offer optimum product protection.

INCREASINGLY BLURRED BOUNDARIES BETWEEN CONVENTIONAL PALLETIZERS AND ROBOT PALLETIZERS.

Today, the boundaries between palletizer families are not very clear-cut. Mixing and matching has always produced beautiful children, and in recent years, palletizer manufacturers and integrators have begun to combine technologies to take the best from each of the two families.

For example, we are increasingly seeing palletizing lines equipped with robots, with highly sophisticated grippers, to pick up entire layers of packages prepared upstream, and achieve significant productivity gains.

COLLABORATIVE ROBOTS OR COBOTS FOR PALLETIZING APPLICATIONS