Integrating a pallet spacer on your palletizer: a few ideas to avoid breakage!

Just as when building a tower, a builder doesn’t start with the roof, or even the foundations, but with a blueprint.Before integrating a non-slip layer pad into your palletizing line, you need to start by building a blueprint.Stabilizing a product, from production to the point of final consumption, remains a challenge for many companies.

If we’ve already convinced you that anti-slip palletizing inserts are the fast, economical and environmentally-friendly solution to your needs, you still have a challenge to meet: making sure that their implementation on your palletizing lines doesn’t end in failure!

Here are a few points to consider:

STEP No. 1: DEFINE THE QUALITY, GRAMMING AND DIMENSION OF YOUR INTERPLAYERThereare several types of non-slip interlayers: paper, solid board, corrugated board, plastic film… Each material is available in a range of grammages, chosen according to its strength, flexibility or the rigidity required to stabilize a pallet. The format of the insert must correspond to requirements.

For example, when placed at the foot of a pallet, it should be the same size as or wider than the pallet itself, to ensure protection. If placed as a layer divider, the format will be smaller or identical to the surface area occupied by the products, so as not to be visible or perforate the palletizing film.

Before moving on to the next step, test the solution in manual mode. There’s no point wearing out your machines and fatiguing your employees if there’s no hope of a winning result.

With 25 years’ experience behind them, our experts will help you refine your choice.

Needhelp? CLICK HERE

STEP 2: IMPLEMENTATION ON THE PALLETIZING LINE

- Define an ideal location for your stack of divider formats.

It’s important to take into account your environmental constraints: hygiene, temperature (hot, cold or extreme cold), hygrometry (dry, damp, wet). Next, you need to check whether the space near the palletizer will be large enough to accommodate a pallet.

There are several types of format stores: some are integrated into the floor or are raised above the ground. Others can directly accommodate a new format pallet, which can then be placed by a pallet truck or automatically conveyed to a location.

Think ahead about easy access for replenishing consumables, and turn your project into a tool for optimizing your internal flows.

- Picking up and dropping off interlayer format.

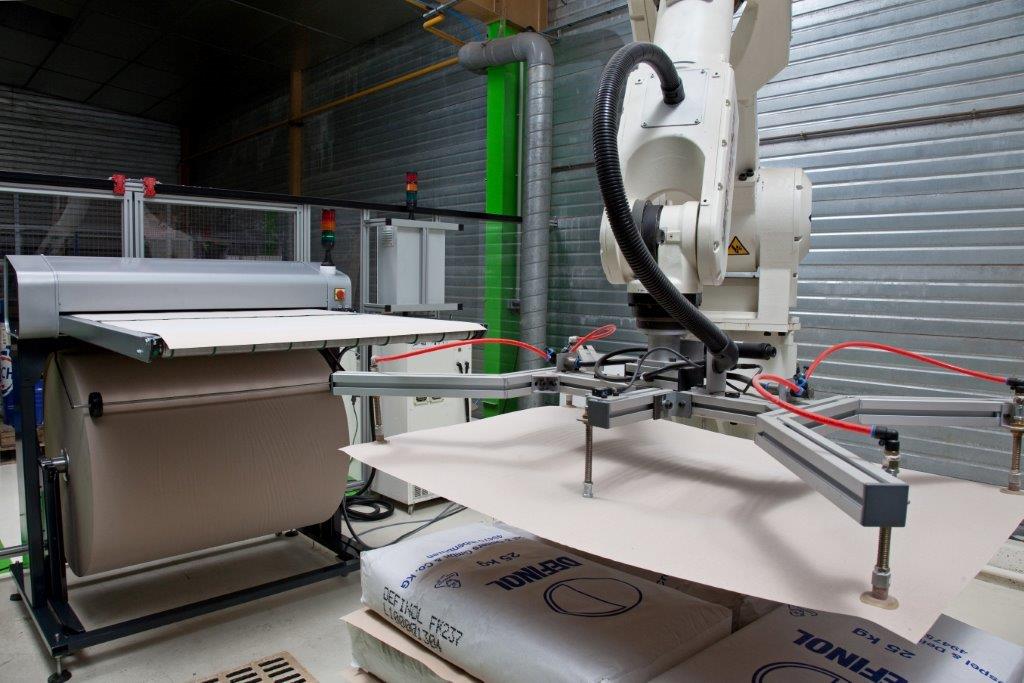

The next step in integrating anti-slip interleaves is the pick-and-place of the interleave format on your pallet. There are different types of gripping systems available, which you can adjust to suit your needs, such as gripper or vacuum gripping.

For suction gripping systems, work on the quality of the suction cups, taking into account their size, their arrangement on the gripper, the suction, but also the speed of maneuvering and the gripper.

Lack of space? Complex circuits? Unstacking problems? Have you ever considered integrating an automatic layer-sheet cutter into your palletizer? Find out how our EXCALIBUR automatic format cutter can help.

STEP 3: ORGANIZE A TEST PROGRAM

The experts at our technical center are here to help you anticipate future adjustments to your palletizing line. Thanks to our palletizing test cell, capable of reproducing your constraints, we can draw up a list of recommendations that will enable you to shorten your lead times and reduce the costs involved in implementing your project.

To find outhow a market leader managed to integrate pallet dividers into its automatic palletizing lines, CLICK HERE.

A team of EXPERTS will support you in your approach, bringing together their know-how, methods and experience to help you implement the changes required by the insertion of layer pads in your palletizing line, without affecting productivity.