More Than 100 Years of History...

"100 years of history and challenges, 100 years of history and innovations, 100 years of history and satisfied customers… and the adventure continues to be written and reinvented!"

Frédéric Froissart, CEO of CGP Coating Innovation.

2014

- CGP opens sales offices in Istanbul, Turkey, and Seoul, Korea.

- Expansion of the product range with anticorrosive papers and films.

- Sale of Multisac activities to Sigoplast.

Due to severe market price deterioration from massive imports, Sofilma halts its extruder operations, continuing only the coiling activities by cutting external films.

2015

- Wormhout plant permanently shuts down, with winding activities transferred to the Parent site.

- Acquisition of Carcial, a corrugated cardboard company, which is integrated into CGP Berry.

- Launch of a digital printing business within CGP Berry.

2016: CGP sells Etiqroll and Gigault, non-strategic companies that have since recovered.

2017: Investment in a coating machine for the Bromont plant (Canada) in 2018, the opening of a sales office in Shanghai (China), and the creation of CGP Online for e-commerce.

In 2018: The acquisition of Fortapack in Monterrey, Mexico, strengthened CGP's distribution capabilities across Mexico and Central America. Additionally, the transformation of the Turkey sales office into CGP Turkey marked the establishment of a local company, enhancing the group's presence in the region.

On March 23, 1918, Maurice Wolf founded the Compagnie Générale des Papiers (CGP) from the former establishments he and Pierre Mazoyer had created together in Paris in 1886. As part of its founding, CGP acquired the Papeteries du Bas-Rhin, which produced bisulfite pulp, operated four paper machines, and had an annual output of 5,000 tons. The company also established a paper processing plant in the 20th arrondissement of Paris.

CGP gradually built a network of sales branches, starting with the first in Roubaix. By 1926, the company had expanded to ten branches located in Algiers, Angers, Bordeaux, Dijon, Marseille, Mulhouse, Roanne, Roubaix, Rouen, and Toulouse.

The company offered a diverse range of products, including bisulfite kraft, refined and colored celluloses, grey phormium, crystal paper, sulfurized paper, parchment, muslin, bubble wrap, tarred paper, waxed paper, interleaved sheets, reinforced materials, and strawboard.

By 1926, the Schweighouse plant had doubled its annual production to 10,000 tons.

However, starting in 1928, significant disagreements emerged among CGP’s shareholders, leading to a family split that weakened the group.

Two brothers, André and Jean Nuger, took charge of CGP. The merger was finalized in December 1935, forming a new company called "La Compagnie Générale des Papiers Féron et Lenfant Réunis."

The company soon faced challenges due to the economic crisis of 1936, followed by the hardships of World War II.

After the war, the factory at Ponts-et-Marais resumed operations, while the plant at La Plaine Saint-Denis continued its activities. Additionally, the company acquired another paper production facility in the Puy-de-Dôme region. At this time, there were 12 sales branches remaining, following the closure of the Nancy and Beauvais branches.

In 1956, CGP expanded its operations by beginning to market corrugated cardboard.

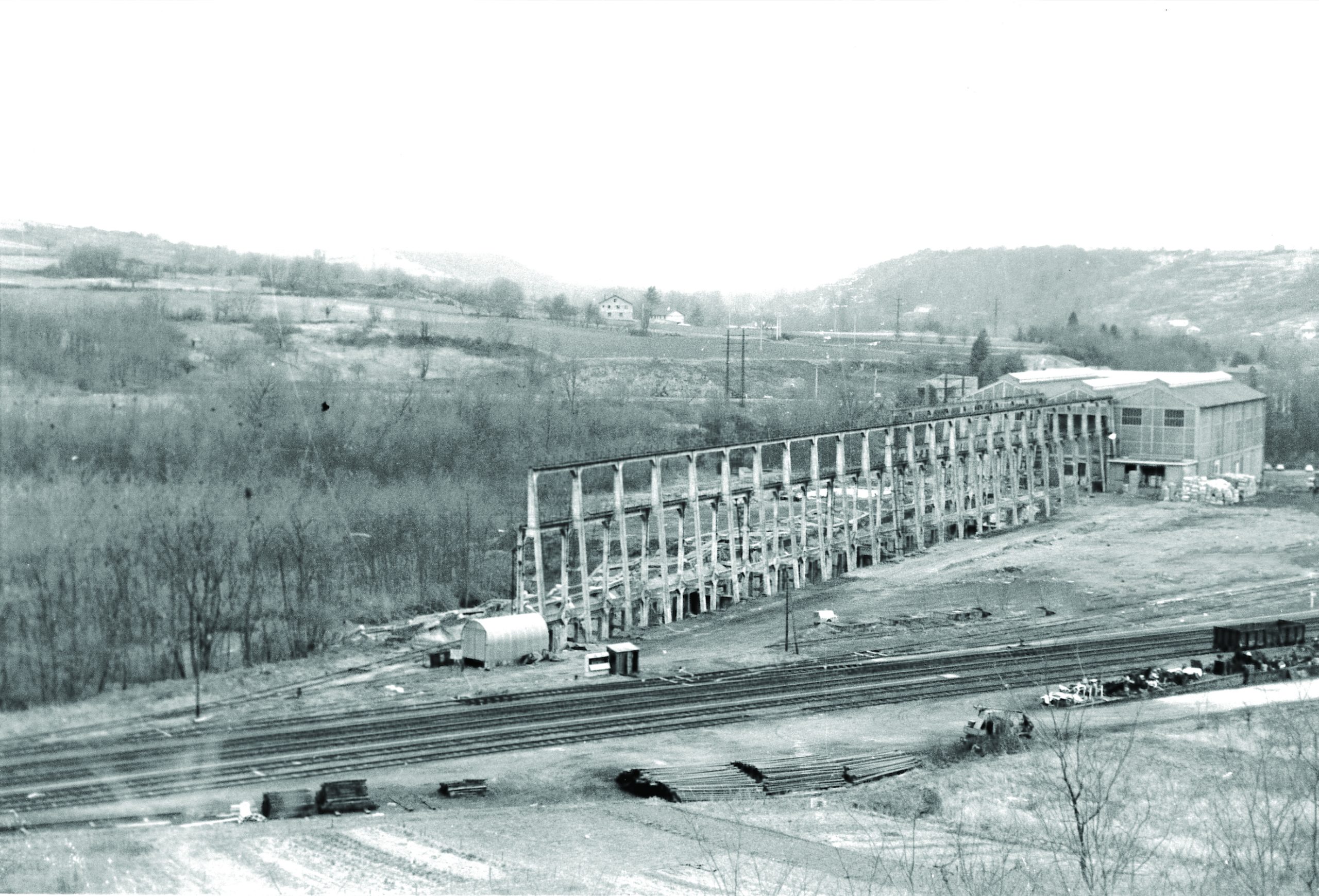

In 1961,CGP purchased a disused thermal power plant from EDF, located in the town of Parent (Puy-de-Dôme), which would long be known as the Coudes factory.

In 1964, We are in the midst of the "Glorious Thirty," a period of rapid economic growth and prosperity following World War II.

- Between 1956 and 1964, turnover grew by 56%, reaching 69 million Francs.

- In 1964, CGP's commercial activity was centered around the distribution of paper packaging and corrugated cardboard, which represented twice the production capacity of the factories. This distribution was managed through 12 sales branches, including the branch in Algiers, which remained operational even after Algeria's independence. CGP served 40,000 clients, with 28,000 of them being regular customers.

- The Ponts et Marais plant, located on the edge of Brazil and covering 20,000 m² on a 7-hectare site, produces 8,000 tonnes of paper annually, including kraft and unbleached interkraft paper (ranging from 64 to 160 g/m²) on a 2.40 m wide paper machine using both virgin and recycled pulp. In addition, the plant also produced crepe paper and launched a corrugator in 1964.

- The Saint-Amant Tallende plant, covering 7,000 m² on a 1.2-hectare site by the Veyre River, produces 5,000 tonnes of kraft and interkraft paper annually, ranging from 40 to 120 g/m², made from both virgin and recycled pulp on a 2.40 m wide paper machine. In 1964, the plant began producing bleached kraft, white cellulose, and colored papers. It also manufactures processed papers, including crepe and paraffin paper. At that time, the plant employed 55 people.

- The La Plaine Saint-Denis factory, covering 3,600 m² on a 6,000 m² site in the urban area of the Paris region, specializes in major transformations in the packaging field. It produces bitumen, reinforced and unarmed papers for maritime packaging, as well as crepe and paraffin papers. The factory is equipped with an aniline flexographic printing line and a rotogravure line. It also houses CGP’s research laboratory.

In 1964, the LA PLAINE SAINT-DENIS factory employed 63 people and was led by Mr. Vermont. - The COUDES factory had no production in 1964.

- The ROYERES plant, located on the edge of the Vézère River, produces 8,000 tons of straw pulp paper and recycled paper annually on a 2.20 m wide paper machine. Additionally, the plant manufactures 13,000 tons of corrugated cardboard on its corrugator and features a modern cashier workshop.

In 1966, the company changed its name to Compagnie Générale des Papiers.

In 1968,the Coudes factory began producing paper.

1973 marked the end of the "Glorious Thirty" years. The year 1974 was particularly challenging for the paper industry, due to a global shortage of pulp and paper. Order books steadily grew throughout 1974, reaching a backlog of 8 to 10 months. However, like all bubbles, this one burst in early 1975, emptying the order books, leading to factory shutdowns, unemployment, and the beginning of significant challenges within the industry.

The production of the three paper mills (excluding Royeres) increased from 18,000 tonnes in 1969 to 24,000 tonnes in 1973. Similarly, the production of processed paper across the four mills rose from 7,000 tonnes in 1969 to 10,000 tonnes in 1973, with a significant increase in crepe paper production from 2,000 tonnes to 4,300 tonnes during this period.

The production of corrugated cardboard at the Ponts et Marais and Uzerche plants grew from 19,000 tonnes in 1970 to 26,000 tonnes in 1973. The distribution of paper and processed paper reached 22,000 tonnes in 1973, while the distribution of corrugated board totaled 12,000 tonnes, with a large portion of the corrugated board being sold directly by Royeres.

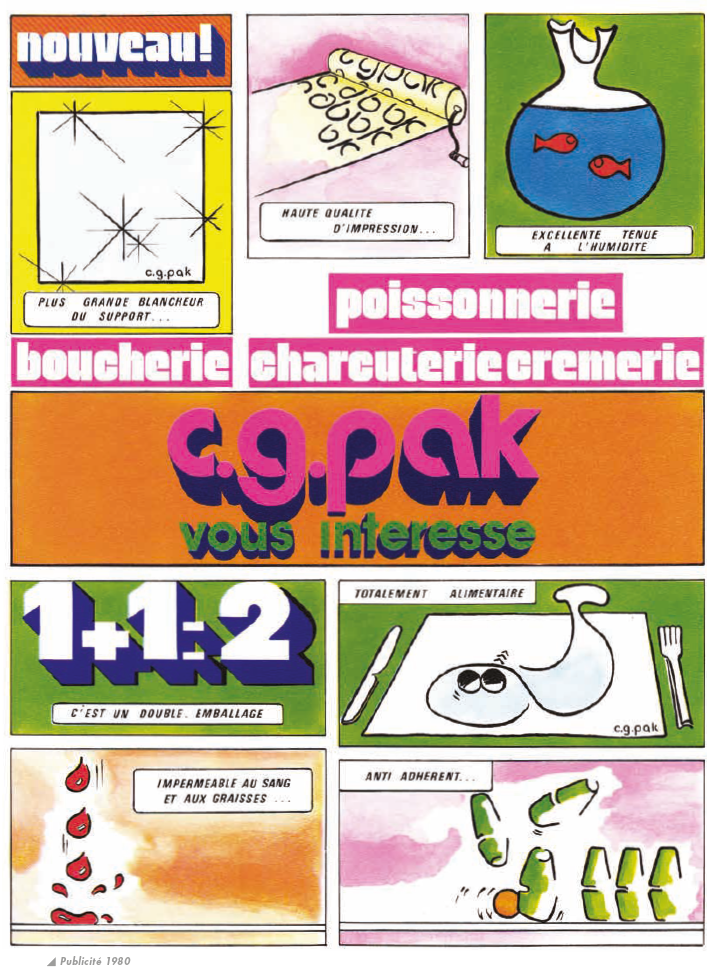

The development of CG PACK (white paper + pasted PEHD film, printed or unprinted in various formats) became a key focus, with the transformation taking place in several branches to provide maximum service to the local trade.

CGP was the first French packaging distributor in 1974 :

Turnover increased from FF 91,953,000 in 1969 to FF 158,684,000 in 1973, marking a 72% rise, despite an inflation rate of 29% during the same period. In 1972, the consolidated group profit before tax and depreciation accounted for 6% of turnover.

By 1973, the number of employees in the group had reached 1,160.

Starting in 1970, the rapid growth of plastic packaging, overtaking paper, led CGP to invest in this emerging sector. In 1975, the company installed a high-density polyethylene (PEhd) extruder at the Coudes plant. This move was unconventional, as most plastic manufacturers typically began with low-density polyethylene (PEbd) before advancing to PEhd. However, CGP had already purchased significant quantities of PEhd for producing ECOPACK. Despite initial challenges, the company launched the GLOENCO extruder in 1975.

Between 1973 and 1980, turnover increased steadily from 158,684,000 Francs to 391,000,000 Francs—a rise of 150% compared to an inflation rate of 100%. However, starting in 1981, turnover began to decline in constant francs, reaching 492,000,000 Francs by 1983.

Between 1980 and 1983, paper activity declined by 15% due to intense competition and price wars driven by increased imports and the strategies of certain manufacturers.

Corrugated board was the most dynamic sector of the group, with a 15% increase in volume between 1980 and 1983. However, CGP remained a minor player in the industry. Exports were minimal, limited to Embalco’s operations in Belgium and paper shipments to Great Britain.

At the beginning of 1984, Henri Bertrand was joined by a general manager, Claude Langlande, who took the first steps toward recovery. These measures included closing the Saint-Amant Tallende plant and consolidating the activities of both plants at the Coudes facility.

The restructuring plan was launched in September 1984:

- Confirmation of the Saint-Amant Tallende factory closure.

- Partial closure of La Plaine Saint-Denis

- A complete reorganization of the headquarters, branches, and factories was undertaken.

- The closure of 9 branches and the Pantin workshop was implemented.

- The plan resulted in the elimination of 259 out of 779 jobs, with Uzerche, Valplast, and Embalco remaining unaffected. The commercial reorganization led to the creation of two divisions:

- The first division, the Industry Division, was organized into three departments: paper and plastic, corrugated cardboard, and supermarkets, covering all manufactured products. Additionally, nine sales officers were appointed, with their sales administration responsibilities being transferred to the factories.

- The second division, the Distribution Division, was established for stock sales and was organized into three regional divisions: Paris, Lyon, and Toulouse, with an additional depot in Nantes.

- The plan proceeded quickly as planned but evolved throughout 1985. Notably, the La Plaine Saint-Denis factory was completely closed.

The restructuring plan launched in 1985 was executed smoothly, without major obstacles. The success of the plan, combined with improvements in the overall economic situation, resulted in a swift recovery for the company, which returned to profitability in 1986.

In 1988, the turnover reached 472 million Francs, with a net profit margin of 6% and a workforce of 671 employees.

In 1988 the turnover reached 472 million Francs, with a net profit margin of 6% and a workforce of 671 employees.

The Novalliance Group experienced a surge of acquisitions, with CGP expanding its portfolio through several key acquisitions: Elce Technologie (special papers) in 1988, Gault and Fremont, Paris Emballage, and Printing Pack (food packaging) in 1990, Gouzy(cosmetic labels) in 1990, Morel and Barneron (perfume boxes) in 1990, VOA (glass bottles) in 1991, Papeteries de la Fourche and Sodipa (food packaging) in 1992, Cartonnage Unic and Thiollat (carton packaging) in 1992, and Gie Gepac and Papeteries du Nord (distribution) in 1992.

In 1989, CGP sold its corrugated cardboard business, including the two factories of Ponts et Marais and Uzerche, as well as the commercial cardboard service, to the Irish group Smurfit, one of the world leaders in the sector. Shortly after this acquisition, Smurfit also acquired the Cellulose group of PIN.

In 1993, the operations and assets of the Coudes factory were transferred to a subsidiary company, CGP Industries, with its headquarters located in Parent.

The parent company, which consolidated all the entities of the packaging group, was renamed Compagnie Générale De Packaging and was managed by Eric Bollore. In 1992, its turnover reached 1,766 million Francs.

This turnover was composed of 41% flat board, 25% distribution, 25% glass, and 9% paper and plastic.

In 1994, ALTUS Altus Finance, a subsidiary of Credit Lyonnais responsible for managing majority assets and headed by J.F. Henin, took over the CGP group. CGP Industries became part of the CDR (Consortium of Realization), which aimed to liquidate all assets, including Elce, which it took control of in 1995. Elce had developed an innovative paper and anti-slip board product for palletizing interlayers, which was gaining popularity. A home-built coating machine had been installed to support production. In 1995, Elce's turnover reached 43 million Francs.

In 1996, through a fortunate series of events, Jacques Petiart (former director of Celta from the Rossmann group) made contact with the Esswell group, led by Jean-Marie Louette, who also directed Dore Emballage. At that time, Esswell was an international corrugated cardboard group with a presence in Spain, Germany, the Netherlands, Italy, and France (including Siemco in Nantes and Dore Emballage in Puy de Dôme). The group's turnover at that point was 1,865 million Francs. Esswell was owned by two associated paper manufacturers, Jan Sjogren and Miguel Saez.

In 1999, after the Esswell group sold its corrugated cardboard business, the group shifted its focus to the essential reorganization of CGP. The merger between CGP Industries and Elce was completed, marking a new chapter in the history of CGP. With the three current shareholders—Jan Sjogren, Miguel Saez, and Jean-Marie Louette—the company entered a new phase of development.

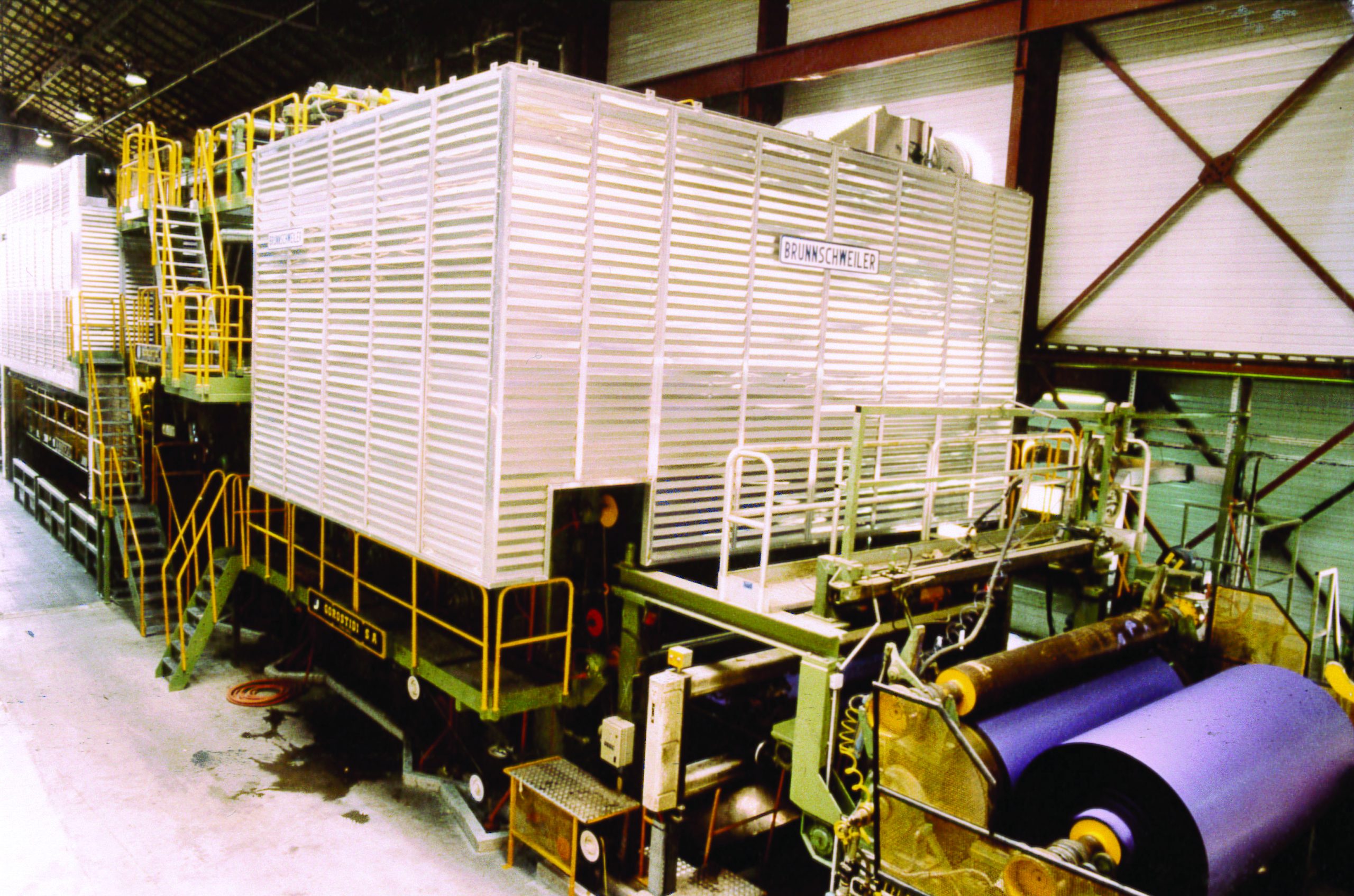

The volumes of anti-slip paper and board were increasing significantly, and the Elce coating machine was no longer sufficient to meet demand. Meanwhile, the production of paper processed at Coudes needed to be reorganized in larger premises to accommodate its growth and allow for further development.

An opportunity arose with a factory in Cebazat, Puy De Dôme, which produced paper for photocopiers and was owned by the American group International Paper. In 1999, CGP acquired this factory along with its coating machine, winding and cutting machines, and took over 30 employees.

Under the operational direction of our Quality Engineer, Frédéric Froissart, who is now the General Manager of the group, the transformation machines from Coudes were quickly transferred to the new facility.

In 2000, a new Uteco film printing machine was installed, and in 2001, a 3-layer co-extruder with a width of 2,200 mm was put into operation.

In 2002, the Elce plant, which had relocated from Caluire to Decines, was shut down, and all activities were transferred to Cebazat.

In 2004, each of CGP's activities became a subsidiary:

- CGP Industries for processed paper

- CGP Film for plastic activities

- Compagnie Générale Des Papiers for paper production

- The parent company was renamed CGP Auvergne

- A new creping machine was installed, and the Alpine 2 single-layer extruder was transformed into a 3-layer co-extruder

The paper mill's situation deteriorated rapidly due to international price competition and the decline of several markets shifting to alternative products. These challenges impacted all French paper packaging groups, excluding those specializing in corrugated cardboard.

The paper mill was further weakened by two fires and a flood of the Allier River in 2004.

After attempts to redirect paper activities toward light PPOs and the failure of external partnerships, CGP permanently ceased paper production in November 2005.

In 2005, In 2005, CGP launched an anti-slip paper processing operation in Canada and established the company CGP Caribou in Saint-Jean-Sur-Richelieu.

In 2006, to further develop its processed paper activities, CGP seized an opportunity and acquired a large factory in Bourges. This facility was equipped with a corrugator for anti-slip cartons, cardboard cutting machines, and a heliogravure printing machine to expand the range of technical paper coatings. That same year, CGP acquired Etiqroll, an adhesive label company in Rochecorbon (37) that was facing financial difficulties. Due to its location near Vouvray, ETIQROLL primarily specialized in producing labels for winegrowers. Following the acquisition, CGP implemented an ambitious investment plan, including the introduction of digital printing and the expansion into industrial markets.

In 2007, CGP decided to invest in the production of high-quality printed films. To support this new activity, a dedicated company called CGP Print was created. An 8-color printing machine was installed in the former paper mill premises. The target markets for this new venture included marketing routing films and food films, complementing the Sofilma market.

In 2008, CGP acquired the activities of Multisac, a company in liquidation based in Puy-En-Velay. Multisac specialized in the production of printed films, laminates, and pouches for the food industry. Following the acquisition, CGP Multisac was established.

The sale of anti-slip papers in Canada expanded, leading to an agreement with a Canadian distributor. In 2008, CGP ExpalL was established in Granby, near Montreal, where a cutter was transferred to convert anti-slip paper rolls produced at Cebazat into sheets. That same year, CGP Eexpert was founded in Bourges to focus on research and development.

In 2009, Sofilma and Multisac are BRC certified.

In 2010 the entity CGP Coating Innovation was created to unify and promote all paper processing activities.

In 2011, CGP Film and CGP Print merged to form CGP Flexible Innovation, with CGP Multisac also joining the new entity. Additionally, CGP acquired a building in Bromont, Canada, and transferred the activities of Expal there. A second acquisition followed in 2018.

Between 2009 and 2012, CGP Industries expanded its export activities for anti-slip paper and board by opening sales offices in Germany, Denmark, the USA, and Mexico.

In 2012 CGP established a company in Germany, with a sales office in Düsseldorf and a factory in Plauen, located near the Czech border.

In 2013, CGP Expert inaugurated the Technical Center in Bourges. The company CGP Coating Innovation North America was also established in Atlanta, USA, with sales offices opened in Atlanta and Ontario, California. That year, CGP acquired Gigault, a company based in Chalonnes-sur-Loire specializing in adhesive labels for winegrowers in Anjou. This family-owned business, which was facing difficulties, was quickly revitalized, and an investment plan was launched to support its recovery.

Newsletter

Retrouvez toutes nos actualités à travers nos newsletters afin d’être informé de nos innovations, nouveautés sur toutes nos solutions, participer à nos événements.

Retrouvez ...

CGP Group

About us

Also to be found

Newsletter

Find all our news through our newsletters to be informed of our innovations, news on all our solutions, participate in our events.

They trust us